- Do you need help? Here Us:

- +86 151 3866 6240

- richard@zzgofine.com

- Mon - Fri: 8am - 20pm

Fertilizer Equipment Supplier

Latest Fertilizer Equipment

Fertilizer mixers play a vital role in fertilizer production. They are mainly used to mix different types of fertilizer raw materials (such as nitrogen fertilizers, phosphorus fertilizers, potash fertilizers), additives (such as trace elements, humic acid) and fillers (such as clay, diatomaceous earth) according to specific formulas and proportions. This ensures that the nutrient content of fertilizer products is uniform and consistent, meeting the needs of crop growth for various nutrients. For example, when producing compound fertilizers, it is necessary to accurately mix nitrogen sources (such as urea), phosphorus sources (such as monoammonium phosphate) and potassium sources (such as potassium chloride) to achieve the ideal nitrogen, phosphorus and potassium ratio, and fertilizer mixers can efficiently complete this task.

Product advantages

High mixing uniformity: The fertilizer mixer can fully mix a variety of fertilizer raw materials through advanced mixing structure and method.

Adjustable mixing degree: The mixing time, mixing speed and other parameters can be adjusted to control the mixing degree according to different fertilizer formulas and usage requirements.

Wide material compatibility: The fertilizer mixer can handle various forms of fertilizer materials, including granules (such as urea granules, compound fertilizer granules), powders (such as trace element powders), pastes (such as humic acid pastes) and liquids (such as liquid fertilizer additives).

Adapt to different formula requirements: Various raw materials can be mixed together in precise proportions, providing flexibility for the production of various types of fertilizers and adapting to the diverse fertilizer product needs on the market.

Efficient mixing capacity: It has high production efficiency and can process a large amount of fertilizer materials in a short time.

Energy-saving advantages: Some modern fertilizer mixers take energy-saving factors into consideration in their design. By optimizing the shape and mixing method of the mixing blades, the energy loss during the mixing process is reduced.

Power: 11-22kw

Stirring shaft outer diameter: 420-650mm

Stirring speed: 35r/min

Size: Customizable

Materials: It is mainly used in the fields of construction, chemical industry, food, feed processing and fertilizer production

Twin-shaft horizontal mixer

Power: 7.5-15kw

Mixing output: 2-12t/h

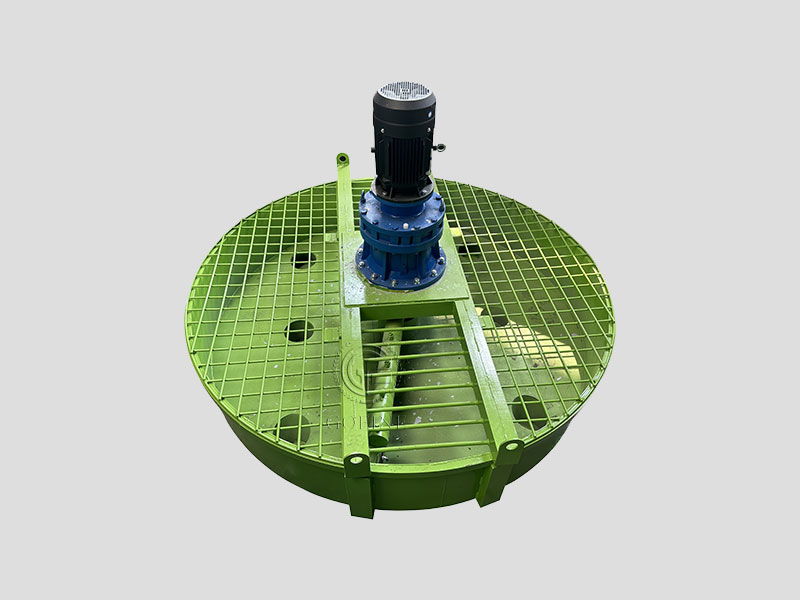

Disc diameter: 160-300cm

Size: Customizable

Materials: The core function is to achieve uniform mixing of multi-component materials

Fertilizer disc mixer

Power: 5.5kw

Discharge capacity: 350L

Mixing output: 10-14m³/h

Mixer drum speed: 14r/min

Size: Customizable

Materials: Different types of fertilizer raw materials are mixed evenly in proportion

BB fertilizer mixer

Power: 7.5-11kw

Main plate thickness: 4-10mm

Mixing speed: 46r/min

Mixing output: 1-15m³/h

Size: Customizable

Materials: Horizontal mixers are widely used in construction, chemical, food, feed, fertilizer and other fields.

Horizontal mixer

Perfect Solution for Industry

Project communication

Scheme design

Equipment production

Installation guidance

Mechanical Technical training